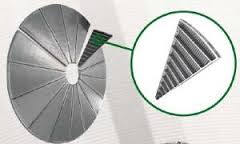

Slot tubes are composed of a surface profile that is spirally wrapped around axial support profiles and connected to each other. The filter elements have the unique advantages of very accurate, narrow slot openings and perfect roundness together.

Tubes can be offered with essential endpieces for connections and/ or reinforcements. During the filter cycle, the solids are accumulated on the smooth surface. The cake acts as an additional filter for finer particles. The fines slop through do not get stuck in the conical slots. Through reverse flow, cake and dirt are removed from the filter surface.

The screens are directly produced as flat screens. This prevents the chance of stress corrosion and weakening of mesh. For special applications such as Nickel mesh applications for alkali media screening is supplied. A combination of different support profiles in single flat screen is feasible. Reinforcements can be added depending on project. Cylinders and conical baskets are produced for this purpose.

The standard cylinder mesh is produced: slot direction is axial and filtration direction is from inside to outside. Smooth surface is at the inside and support profiles are the outside.

When a scraper blade is used, it is needed that supports are at the outside and slots are radial. It is called reverse rolled slot tube. Woven mesh screens are used as flat filters or processed to fabricate cylinders.

Flat screens are static sieves for dewatering or classification. The screen is set up at a specific angle or is curved therefore surface profiles are perpendicular to the filtration direction. Through gravitation the slurry flows over the screen. Vibrating screens, dryers and coolers, screens used as support for the product that needs to be treated.

Band filters: Screen as support for paper or textile, for instance for the separation of cutting oil support screen. For this application, the screens are configured inside the vessels to support catalyst, molecular sieve and beer bottoms.

Drum screen with or without internal transport screw. Centrifuge baskets and cylinders for food, paper and pulp industry, starch and screw presses.

Mesh screens are commonly used in sieve bends, starch screens, candle filters, nozzles, resin traps, rotary screen, distributor and collector laterals.

High strength Mesh screens produced by perforated mesh are mainly used in sifting and grading in mine development and other industrial applications. They are also used support layer, as core of filter or surface screen to increase the service life or improve its strength. Perforated sheet or sintered mesh are used as filter media.

Perforated mesh can be produced of different alloy grades such as stainless steel, Inconel, Monel and Hastelloy grades to fabricate sintered mesh sheet for high precision performance. Perforated sheet is sintered through vacuum sintering, compression and rolling and made into a type of porous material.

Strainers have become the popularly used device in liquid pumping applications. They are used to protect piping equipment like valves, flow meter and others. The essential thing is to choose the right strainer for which you can take help of a professional mesh manufacturer. Contact us today.